Best Overview to Preventing Weld Undercut: Tips and Techniques

Best Overview to Preventing Weld Undercut: Tips and Techniques

Blog Article

Comprehending the Causes and Solutions for Undercut Welding in Steel Construction Procedures

In the world of steel construction procedures, the occurrence of undercut welding poses a considerable difficulty that demands a detailed understanding of its reasons and feasible options. The complex interplay of different elements during welding operations can lead to this undesirable phenomenon, influencing the architectural honesty and general high quality of the welded joints - Preventing weld undercut. By dissecting the root creates of undercut welding and discovering reliable restorative steps, producers can elevate the criterion of their handiwork and make sure the production of flawless steel parts

Typical Reasons For Undercut Welding

Regularly forgotten in metal fabrication, undercut welding happens due to different variables that require meticulous attention and competence to be properly mitigated. Additionally, improper welding techniques, such as utilizing the wrong welding angle or travel speed, can likewise contribute to undercut formation. The option of welding specifications, such as voltage, present, and cable feed speed, plays a considerable function in the incident of undercut welding.

Effect of Incorrect Welding Parameters

Imprecise welding parameters can substantially endanger the integrity and high quality of bonded joints in steel fabrication processes. The effect of wrong welding criteria manifests in different methods, leading to architectural weak points and defects in the welded elements. Careful focus to welding parameters is paramount to guarantee the manufacturing of high-grade welds with the wanted mechanical residential or commercial properties and structural stability.

Impact of Improper Lantern Angle

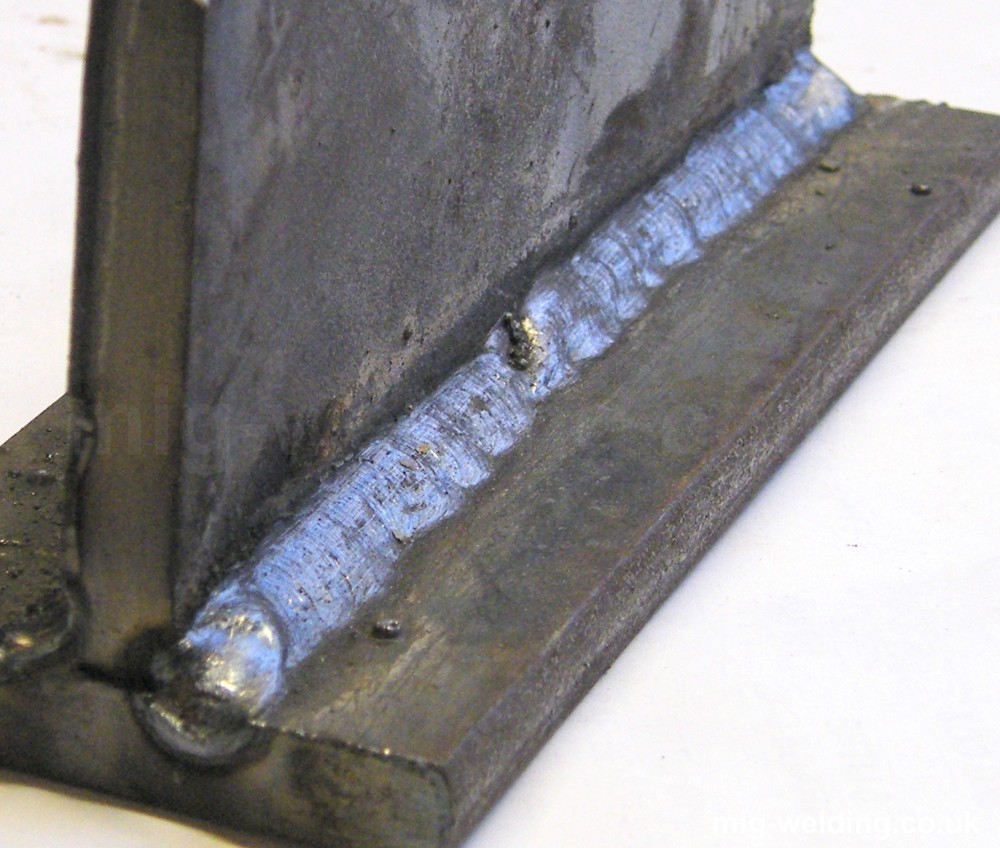

Incorrect lantern angle in welding operations can considerably affect the high quality and stability of the final weld joints in steel manufacture procedures. Undercutting is a common welding defect where a groove creates along the weld toe, damaging the joint and endangering its structural integrity.

A lantern angle that is as well steep can result in insufficient infiltration, insufficient combination, and enhanced spatter. On the other hand, a lantern angle that is as well shallow can result in too much infiltration, burn-through, and distortion of the base material. Preventing weld undercut. Proper lantern angle is necessary for making sure consistent weld quality, toughness, and appearance

To avoid damaging and various other problems brought on by inappropriate torch angles, welders must be educated to maintain the proper lantern angle throughout the welding process. Normal monitoring and change of torch angles throughout welding can assist achieve sound welds with minimal issues.

Duty of Inadequate Welding Methods

Another aspect of inadequate welding techniques is improper weld prep work. Poor cleansing of the base steels, see post wrong joint style, or inadequate edge preparation can all add to undercut welding. Inadequate shielding gas insurance coverage or making use of the wrong type of gas can result in insufficient blend and the formation of undercut problems.

To address the duty of insufficient welding methods in metal manufacture processes, it is important to provide comprehensive training for welders. Correct education on welding parameters, joint prep click here for info work, and protecting gas option can assist avoid undercut welding and ensure high-grade welds in steel fabrication tasks.

Efficient Solutions for Undercut Welding

Addressing undercut welding in steel fabrication calls for executing reliable options to enhance weld high quality and structural stability. One of the main solutions to deal with undercut is to readjust welding criteria such as voltage, existing, and travel speed to ensure proper heat input and combination. By fine-tuning these settings, welders can stop excessive melting of the base steel and filler product, decreasing the chance of undercut formation.

In addition, proper joint preparation is crucial in stopping undercut. Ensuring clean base steel surface areas totally free of impurities and using the suitable bevel angle can aid promote much better weld infiltration and lower the risk of undercut - Preventing weld undercut. Utilizing ideal welding techniques, such as weaving or oscillating the torch, can additionally aid in distributing warm uniformly and loading the weld joint properly, lessening the opportunity of undercut issues

Furthermore, choosing the right welding consumables, consisting of electrodes and filler steels, is crucial in mitigating undercut. Utilizing materials with proper chemical make-ups and mechanical properties can add to achieving sound welds with minimal undercut. Regular evaluation and quality assurance procedures must likewise be carried out to find and address undercut issues promptly, ensuring the overall integrity of made steel parts.

Final Thought

Finally, comprehending the causes and services for undercut welding in metal fabrication procedures is critical for attaining top notch welds. By attending to typical causes such as inaccurate welding criteria, incorrect torch angle, and inadequate welding strategies, welders can stop undercutting and ensure solid, sturdy welds. It is necessary to take note of these elements and implement reliable options to improve the total welding process and final item high quality.

Report this page